Preservation For The New Millennium

Cortec® VpCI®-126 Blue & VpCI®-386!

One of the biggest challenges in

maintaining spares and redundant

machinery in a prime state, ready for

operation, is keeping it all from corrosion

and deterioration. The process can be an

expensive and overwhelming proposition.

Proper preservation techniques during

storage and machinery mothballing are

becoming extremely important as cost of

downtime and machinery repairs

escalates.

When asset safeguarding is required for periodic or seasonal lay-up or longer term mothballing,

Cortec’s Patented Vapor phase Corrosion Inhibitor (VpCI®) products provide a low-cost, easy-to-apply

solution that will preserve property for periods of several months to over 15 years. In a vast

majority of cases, a conscientiously executed preservation program will pay for itself very

rapidly.

A well-known, world leading manufacturer of construction and mining equipment, diesel and

natural gas engines, industrial turbines and diesel-electric locomotives, has recently used Cortec’s

environmentally safe products to protect their heavy equipment against corrosion during storage

and shipment.

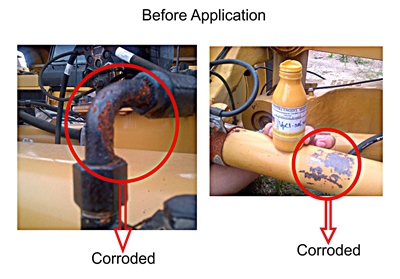

One of the first problems that the client had was corrosion free storage of over stock surplus.

They kept them in a yard that was close to the sea and due to the length of time they had been

kept there, some sections of the equipment’s paints were blistered and cracked leaving the bare

plate exposed to the sea environment, which caused corrosion. To overcome this issue, the

engineer was using conventional paint to cover corroded areas, however, after one-two months

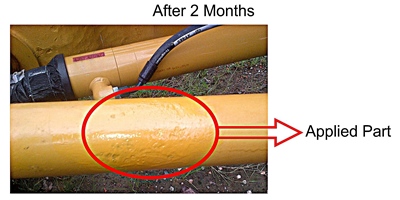

the paint was cracked and the parts were corroding again. To solve the issue, Cortec’s VpCI®-386 was applied to those areas that were cracked and corroded. An inspection after 3 months showed

that the coating applied had protected the equipment and showed no further signs of corrosion.

VpCI®-386 is a unique water-based acrylic primer/topcoat that successfully provides protection in

harsh, outdoor, unsheltered applications. The complex mixture of non-toxic organic inhibitors

offers protection that can compete with most paints and zinc-rich primers. VpCI®-386 is superior

to many other coatings with inorganic pigments because the resistance has been improved by

replacing pigments and metal oxides with more effective organic corrosion inhibitors. The special

combination of additives provides a composite polymer barrier that significantly retards the

reaction of metal ionization. A protective film is adsorbed onto metal surfaces. It protects against

corrosive electrolytes and aggressive environments; preventing corrosion. VpCI®-386 provides a

fast-drying thixotropic coating that is resistant to sagging or running, forming a tough, nonflammable,

protective barrier. This dry-to-touch film offers extended protection for outdoor or

indoor conditions. Thermally stable when dried from -150°F to 350°F (-78°C to 180°C). The

coating is ultraviolet resistant giving optimal outdoor performance without cracking or chipping

upon prolonged exposure to sunlight.

This well-known client was also looking for the best corrosion protection method to ship big

generators from Brazil to Japan. The ocean trip would take approximately 90 days and the

generators needed to arrive corrosion free. To resolve the problem and receive continuous

protection against salt, excessive humidity, condensation, and moisture, Cortec® VpCI®-126 Blue

was draped over the equipment, the edges were sealed with water proof tape, and then a thick tarp

was placed over the film to further protect the equipment. When the generators arrived in Japan,

there were no visible signs of corrosion.

Cortec’s Vapor phase Corrosion Inhibitor (VpCI®)-126 Series films combine the latest film

technology with the most effective corrosion protection for all of your metal products. Cortec®

VpCI® films protects metal parts from all types of corrosion including rust, tarnish, stains, white

rust, and oxidation for up to several years. The film replaces conventional rust preventatives such

as oil and desiccants.

It is extremely important for Cortec® and its distributors to make sure that the client’s satisfaction

with the product and application is achieved. The people involved in these projects greatly

appreciated the efforts in the successful completion of the equipment preservation and expressed

abundant satisfaction with the way the projects’ results turned out.